Market Overview:

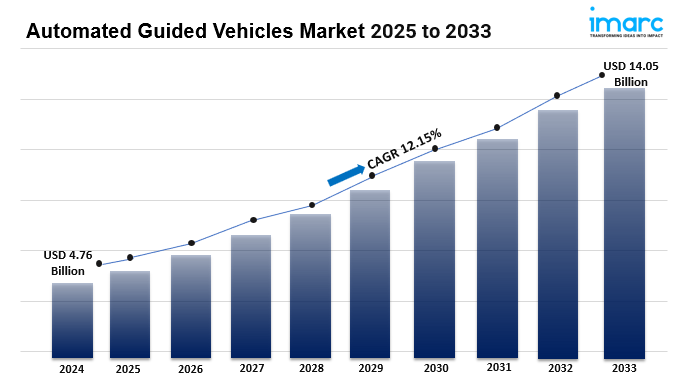

The global automated guided vehicles (AGVs) market is experiencing significant growth, driven by increasing adoption across manufacturing, logistics, and warehousing industries. AGVs enhance operational efficiency, reduce labor dependency, and improve safety by automating material handling tasks. The market, valued at USD 4.76 billion in 2024, is projected to reach USD 14.05 billion by 2033, with a CAGR of 12.15%. This growth is fueled by advancements in technology and the rise of Industry 4.0, which integrates AGVs into smart, connected manufacturing environments.

STUDY ASSUMPTION YEARS:

-

- Base Year: 2024

- Historical Years: 2019-2024

- Forecast Years: 2025-2033

AUTOMATED GUIDED VEHICLES MARKET KEY TAKEAWAYS:

- The global market is expected to grow from USD 4.76 billion in 2024 to USD 14.05 billion by 2033, with a CAGR of 12.15%.

- Europe holds a leading market share of over 34.1% in 2024.

- The rise of automation in manufacturing, logistics, and warehousing is a key driver.

- Labor shortages and safety concerns are major factors fueling AGV adoption.

- Technological advancements in AI and machine learning are enhancing AGV capabilities.

- The integration of AGVs with Industry 4.0 technologies is a significant trend.

- Strategic collaborations and innovations by key players are accelerating market growth.

MARKET GROWTH FACTORS:

Technological Advancements: This is an age where technology-development gains can be attached to gradual demand heightening for AGVs and vice versa. Technological advancements in AI, machine-learning models, sensor technology, etc. have imparted operations with better precision, efficiency, and flexibility in implementation. These are axes along which further integration of operations can be elaborated. Asization towards sophistication, the tasks allocated to the AGVs have climbed in ambition from navigation through dynamic environments to route-optimization and precision. Following emerging affordability trends, the technologies are making AGVs cheaper and hence affordable to a working business.

Labor shortages and safety concerns: One large industrial facet facing labor shortage has been logistics and manufacturing. Increasing difficulty in hiring and keeping competent operators has pressed AGVs to become a necessity. These vehicles would undertake tasks that are repetitive and laboring, sometimes truly dangerous work, that otherwise would require the intervention of humans who face an unfortunate risk of injury at a workplace. On the very operational side of safety, implement AGVs to do hazardous work-lifting heavy loads in the dangerous area. With labor shortages present at all times, ensuring uninterrupted operation by AGVs will be a necessity.

Integration with Industry 4.0: With Industry 4.0 on the anvil, installing automation systems for carrying out data exchange in manufacturing technologies remains an important reason for tackling the AGV market. The AGVs become part of interconnected, smart manufacturing systems that boost operational efficiency, productivity, and availability of real-time information. This will allow smooth-running inventories on Undermainputory planning pathways for businesses. Thus, there shall be an incline for the AGVs in all such industries in accordance with Industry 4.0 tenets, positioning them at the forefront of modern manufacturing.

Request Sample For PDF Report: https://www.imarcgroup.com/automated-guided-vehicles-market/requestsample

Market Segmentation:

Analysis by Type:

- Tow Vehicles

- Unit Load Carriers

- Pallet Trucks

- Assembly Line Vehicles

- Forklift Trucks

Analysis by Mode of Operation:

- Indoor

- Outdoor

Analysis by Navigation Technology:

- Laser Guidance

- Magnetic Guidance

- Inductive Guidance

- Optical Tape Guidance

- Vision Guidance

- Others

Analysis by Application:

- Transportation

- Distribution

- Storage

- Assembly

- Packaging

- Waste Handling

Analysis by Industry:

- Automotive

- Manufacturing

- Food and Beverages

- Aerospace

- Healthcare

- Logistics

- Retail

- Others

Market Breakup by Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Key Players:

- Bastian Solutions LLC (Toyota Industries Corporation)

- Daifuku Co. Ltd.

- Ek Robotics Gmbh

- IKV Robot Nanchang Co. Ltd.

- John Bean Technologies Corporation

- Jungheinrich AG

- Kion Group AG

- KUKA Aktiengesellschaft

- Murata Machinery Ltd.

- Schaefer Systems International Pvt Ltd.

- Scott Systems International Inc.

- Simplex Robotics Pvt. Ltd.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.