Designing marine exhaust systems for large vessels involves a complex interplay of engineering, environmental considerations, and regulatory compliance. Unlike smaller boats, large vessels face unique challenges due to their size, power requirements, and operational environments. In this blog, we will explore the key considerations for designing effective marine exhaust systems for large vessels, focusing on factors that influence performance, safety, and environmental impact.

Understanding Marine Exhaust Design for Large Vessels

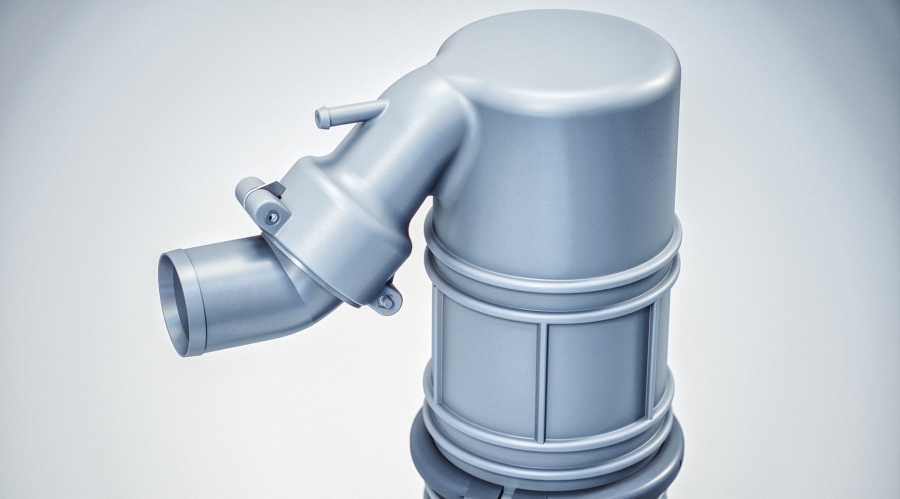

Marine exhaust systems are essential for managing and expelling the exhaust gases produced by a vessel’s engines. For large vessels, these systems must handle greater volumes of exhaust and cope with additional stresses such as high temperatures and corrosive marine environments. Proper marine exhaust design ensures that exhaust gases are efficiently managed, noise is reduced, and emissions are controlled in accordance with environmental regulations.

Key Considerations for Marine Exhaust Design

1. Engine Power and Exhaust Volume

Large vessels typically have multiple high-powered engines, resulting in substantial exhaust gas volumes. Designing a marine exhaust system for such vessels requires:

- Capacity Planning: The system must be designed to handle the total exhaust volume produced by all engines, ensuring that it can cope with peak load conditions without excessive backpressure.

- Duct Sizing: Exhaust ducts and pipes need to be appropriately sized to accommodate the large volume of gases. Proper sizing minimizes turbulence and maintains efficient flow, preventing any performance issues.

2. Thermal Management

Managing the high temperatures generated by large engines is crucial for the longevity and efficiency of the exhaust system. Key considerations include:

- Heat Resistance: Materials used in the exhaust system, such as pipes and mufflers, must be capable of withstanding high temperatures. Stainless steel and other heat-resistant alloys are commonly used for their durability.

- Cooling Systems: Integrating cooling mechanisms such as water injection or heat exchangers helps manage exhaust temperatures. Cooling systems prevent overheating, reduce thermal stress on components, and enhance overall system performance.

3. Corrosion Resistance

The marine environment is highly corrosive, which can significantly impact the lifespan and effectiveness of exhaust systems. To mitigate corrosion:

- Material Selection: Use corrosion-resistant materials, such as marine-grade stainless steel or composite materials, to ensure durability and longevity in the harsh marine environment.

- Protective Coatings: Applying protective coatings to exhaust components can further enhance their resistance to corrosion and extend their operational life.

4. Noise Reduction

Reducing noise is an important consideration for large vessels, especially those operating in busy ports or near populated areas. Effective noise reduction strategies include:

- Muffler Design: Incorporate advanced muffler designs that are capable of handling high exhaust volumes while reducing noise levels. Multi-chamber and expansion chamber mufflers are often used for their effectiveness in sound attenuation.

- Isolation: Use vibration isolation techniques to prevent noise from traveling through the vessel’s structure. Rubber mounts and isolators can help minimize vibration-related noise.

5. Emission Control

With stringent regulations on emissions, controlling exhaust gases is a top priority. Considerations for emission control include:

- Catalytic Converters: Install catalytic converters to reduce harmful emissions such as nitrogen oxides (NOx) and hydrocarbons (HC). These devices facilitate chemical reactions that convert pollutants into less harmful substances.

- Scrubbers: For vessels using high-sulfur fuels, exhaust gas scrubbers are essential for removing sulfur oxides (SOx). These systems neutralize sulfuric acid and reduce environmental impact.

- Low-Sulfur Fuels: Implementing the use of low-sulfur fuels can reduce the need for extensive scrubber systems and help comply with international regulations.

6. Regulatory Compliance

Large vessels must adhere to various international and local regulations regarding emissions and exhaust management. Key regulations to consider include:

- International Maritime Organization (IMO) Standards: Ensure that the marine exhaust design complies with IMO regulations such as MARPOL Annex VI, which sets limits on sulfur content in fuels and other emissions.

- Local Environmental Regulations: Be aware of and comply with local environmental laws that may impose additional restrictions or requirements for exhaust emissions.

7. Maintenance and Accessibility

Regular maintenance is crucial for the reliable operation of marine exhaust systems. Considerations for maintenance include:

- Accessibility: Design the system with accessibility in mind, ensuring that key components such as filters, catalytic converters, and mufflers are easily reachable for inspection and servicing.

- Inspection Points: Incorporate inspection ports and access panels to facilitate routine checks and maintenance activities without requiring extensive disassembly.

8. Integration with Other Systems

Marine exhaust systems must be integrated with other onboard systems, such as:

- Engine Control Systems: Ensure that the exhaust system is compatible with the vessel’s engine control systems, including sensors and monitoring equipment.

- Ventilation Systems: Coordinate with the vessel’s ventilation systems to prevent the accumulation of exhaust gases in enclosed spaces and maintain a safe working environment.

Emerging Trends in Marine Exhaust Design

As technology advances, new trends are shaping marine exhaust design for large vessels. Some of these trends include:

- Hybrid and Electric Propulsion: The development of hybrid and fully electric propulsion systems offers a cleaner alternative to traditional marine engines, reducing reliance on fossil fuels and minimizing emissions.

- Smart Monitoring Systems: The integration of smart sensors and real-time monitoring systems allows for more precise control and management of exhaust emissions, leading to improved efficiency and compliance.

- Advanced Materials: Ongoing research into new materials promises to enhance the performance and durability of marine exhaust systems, making them more resilient to extreme conditions and corrosion.

Conclusion

Designing marine exhaust systems for large vessels requires careful consideration of various factors, including engine power, thermal management, corrosion resistance, noise reduction, and emission control. Effective marine exhaust design is essential for ensuring compliance with regulations, protecting the environment, and maintaining the performance and safety of the vessel. By staying informed about emerging trends and integrating advanced technologies, marine engineers can develop exhaust systems that meet the demands of modern maritime operations while minimizing environmental impact.