In the demanding world of industrial maintenance, the need for dependable cold vulcanizing adhesives cannot be overstated. Industries that rely on conveyor belts, rubber linings, and rubber-to-metal bonding often turn to premium solutions for effective and lasting results. For years, Rema Tip-Top SC 2000 has been one of the top choices globally. However, as the market evolves, businesses are exploring other trusted names. One name gaining widespread attention is Oliver Rubber – A Rema Tip-Top Alternative that delivers on performance, cost-effectiveness, and reliability.

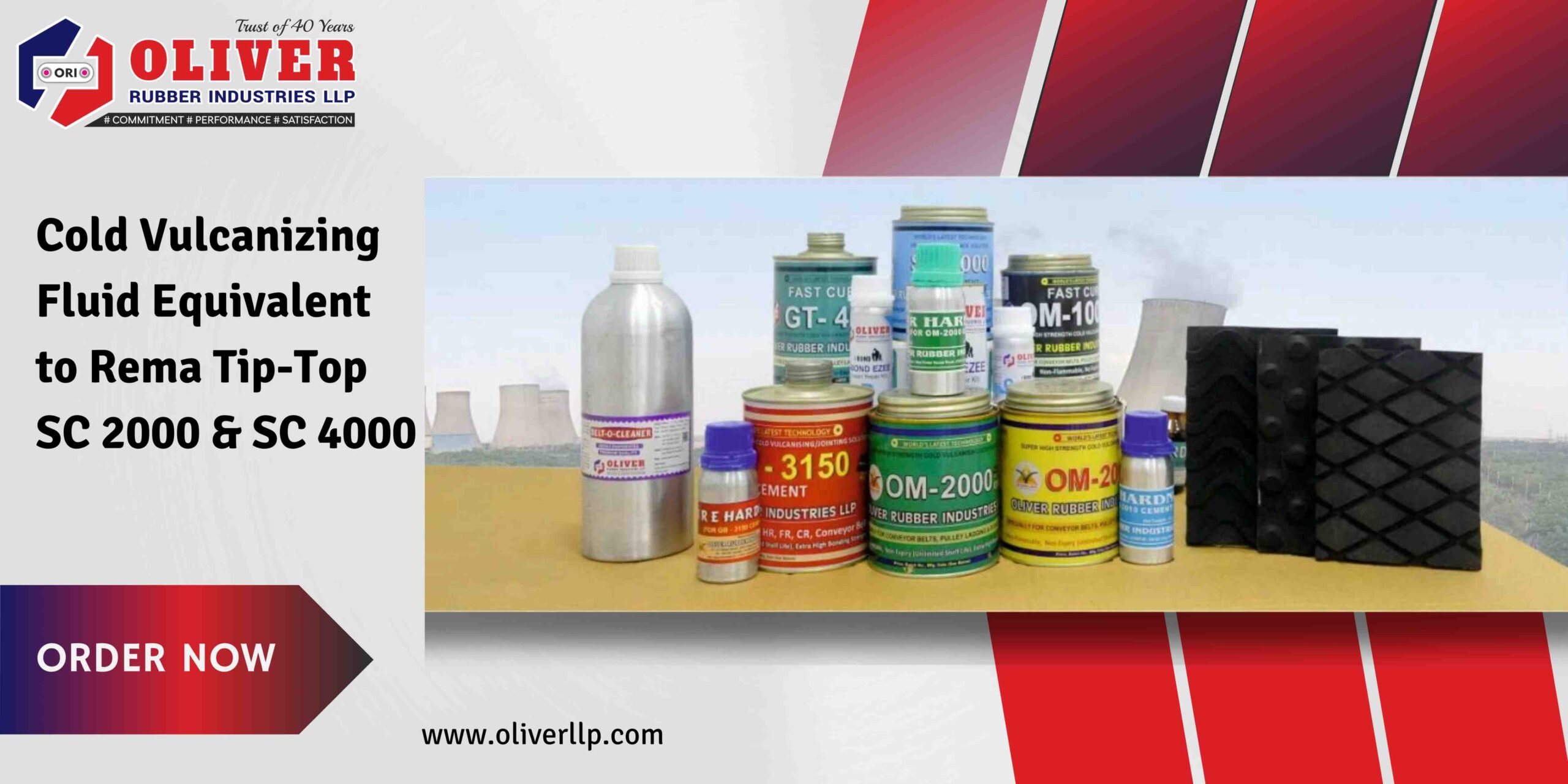

Oliver Rubber LLP, an India-based manufacturer of high-quality rubber products, has developed the OM 2000 Cold Vulcanizing Adhesive—an industrial-grade solution engineered to meet the rigorous standards of modern-day operations. The product has been recognized not only in India but also across the Middle East, including Dubai, as an OM 2000 alternative of Rema Tip-Top SC 2000.

Why Choose Oliver Rubber as a Rema Tip-Top Alternative?

When looking for cold vulcanizing adhesives, businesses prioritize bonding strength, application ease, curing speed, and durability. Oliver Rubber LLP has taken these needs seriously, producing a product that rivals even the most established brands. Here’s why Oliver Rubber A Rema Tip-Top Alternative is gaining ground:

1. High Bonding Strength

OM 2000 Cold Vulcanizing Adhesive offers a powerful bond between rubber, metal, and fabric surfaces. This ensures lasting repairs and minimizes the frequency of maintenance. For conveyor belt jointing or pulley lagging, bonding strength is crucial—and OM 2000 excels in this department.

2. Cold Application – No Heat Required

One of the most significant advantages of OM 2000 is its ability to perform at room temperature. Unlike hot vulcanization, which requires specialized equipment and heat, OM 2000 simplifies the process, allowing on-site and emergency repairs without added complexity.

3. Quick Curing Time

Downtime is costly. With OM 2000, the curing process is fast, ensuring quicker turnaround times. This makes it a preferred choice for industries where operational delays can result in heavy losses.

4. Versatility

The adhesive is suitable for a wide range of applications, including:

Conveyor belt jointing and splicing

Pulley lagging

Rubber lining of tanks and pipes

Bonding rubber to metal and rubber to fabric

Such versatility highlights the utility of OM 2000 alternative of Rema Tip-Top SC 2000 across various sectors, from mining and cement to power plants and steel industries.

What Makes OM 2000 a Trusted Name?

Oliver Rubber LLP has built its reputation by offering high-performance rubber maintenance solutions. Their commitment to innovation, product quality, and customer satisfaction has made Oliver Rubber A Rema Tip-Top Alternative in various regions, including the UAE.

Some key features of OM 2000 include:

High Adhesion: Provides strong bonding in extreme environments.

Room Temperature Application: Works effectively up to 60°C.

Green Color: Allows easy visibility during application.

Shelf Life: Long-lasting when stored in cool, dry conditions.

Convenient Packaging: Supplied in 1kg adhesive and 70g hardener packs.

Applications of OM 2000 Cold Vulcanizing Adhesive

Conveyor Belt Splicing

For industries relying on continuous belt operations, OM 2000 offers a secure, long-lasting joint that stands up to tension and wear. Whether it’s M-24, DIN-X/Y/Z, or nylon-based belts, OM 2000 performs exceptionally well.

Pulley Lagging

Ensuring rubber sheets bond firmly to metal pulleys enhances operational efficiency. OM 2000 is ideal for this task, reducing slippage and increasing the life of the pulley.

Rubber Lining

OM 2000 works well for tank and pipe linings where a strong rubber-to-metal or rubber-to-fabric bond is essential.

Rubber to Metal Bonding

OM 2000 creates high-strength, reliable joints between dissimilar surfaces, ensuring that machines and structures maintain their integrity under stress.

Benefits of Choosing Oliver Rubber over Traditional Brands

No Specialized Equipment Needed: Cold vulcanizing means less investment in heating tools.

Quick Repairs: Ideal for urgent fixes and scheduled maintenance.

Environmentally Safer: Lower energy consumption and safer handling.

Cost-Effective: Offers better value for money than imported alternatives.

In a competitive market, OM 2000 alternative of Rema Tip-Top SC 2000 delivers value and performance that industrial users can trust.

The Verdict: A Smart Choice for Modern Industry

Choosing the right cold vulcanizing adhesive is critical for long-term success in industrial operations. Oliver Rubber A Rema Tip-Top Alternative offers a reliable, proven solution for businesses seeking performance without compromise.

For industries in Dubai and across the globe looking for a Rema Tip-Top SC 2000 replacement, OM 2000 by Oliver Rubber LLP is more than just an alternative—it’s a better way forward.

To learn more or to place an order, contact Oliver Rubber LLP or visit your nearest industrial supplier in the UAE.

Need expert advice? Looking for bulk pricing? Contact Oliver Rubber LLP today and experience why more industries are switching to the OM 2000 alternative of Rema Tip-Top SC 2000.