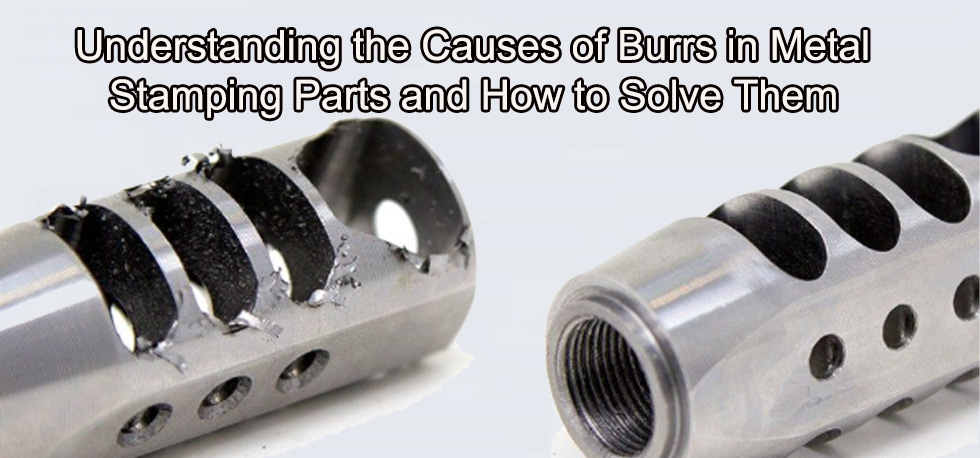

In the manufacturing industry, stamping processes are widely used to produce metal parts with precision and efficiency. However, one common defect that can occur during stamping is the formation of burrs—sharp ridges or rough edges left on the material after the process. Among these, unilateral burrs, which appear on only one side of the stamped part, pose particular challenges. Understanding what are the causes of unilateral burr in stamping parts is crucial for quality control and optimizing manufacturing processes.

What Are Unilateral Burrs?

Unilateral burrs are irregularities that develop on one surface or edge of a stamped component. Unlike symmetrical burrs that appear on both sides, unilateral burrs can compromise the part’s functionality, appearance, and safety. These imperfections often lead to increased secondary processing costs and can reduce the overall efficiency of the production line.

Common Causes of Unilateral Burr in Stamping Parts

1. Tool Wear and Damage

One of the most prevalent causes of unilateral burrs is tool wear or damage. Over time, stamping dies and punches may develop uneven surfaces or dull edges, which can cause excessive deformation on one side of the material. When this occurs, the burrs tend to form predominantly on the side where the tool is worn or damaged.

2. Improper Die Alignment

Accurate die alignment is critical for achieving clean and precise stamped parts. Misalignment between the punch and die can lead to uneven forces exerted during stamping, resulting in unilateral burr formation. Ensuring proper setup and regular calibration of tools is essential for minimizing this cause.

3. Material Issues

The quality, thickness, and hardness of the material can significantly influence burr formation. Variations in material properties can cause uneven deformation during stamping. For example, brittle materials or those with inconsistent thickness can favor the development of unilateral burrs on the side experiencing more stress.

4. Incorrect Stamping Parameters

Stamping parameters such as pressure, speed, and clearance must be carefully controlled. Excessive force or improper clearance can cause uneven material flow, leading to burrs concentrated on one side. Adjusting these parameters appropriately can help prevent unilateral burr development.

5. Insufficient Lubrication

Lubrication reduces friction between the die and the material. Insufficient lubrication can cause localized heating and uneven force distribution, which may result in unilateral burr formation. Proper lubrication practices are vital for smooth material flow and avoiding defects.

Prevention and Control Measures

Understanding what are the causes of unilateral burr in stamping parts helps manufacturers implement targeted measures. Regular maintenance of tools, precise die alignment, proper material selection, optimized stamping parameters, and thorough lubrication are critical steps in reducing burr defects. Additionally, adopting advanced monitoring systems can detect early signs of tool wear or misalignment, allowing for timely corrections.

Conclusion

Unilateral burrs in stamping parts can be minimized through diligent maintenance, precise tooling, and optimized process parameters. By understanding the root causes, manufacturers can improve product quality, reduce waste, and enhance overall production efficiency. For more in-depth insights, visit the Readella homepage or explore what are the causes of unilateral burr in stamping parts.